Why should you work with us?

Multiple highly modern manufacturers to benefit customers

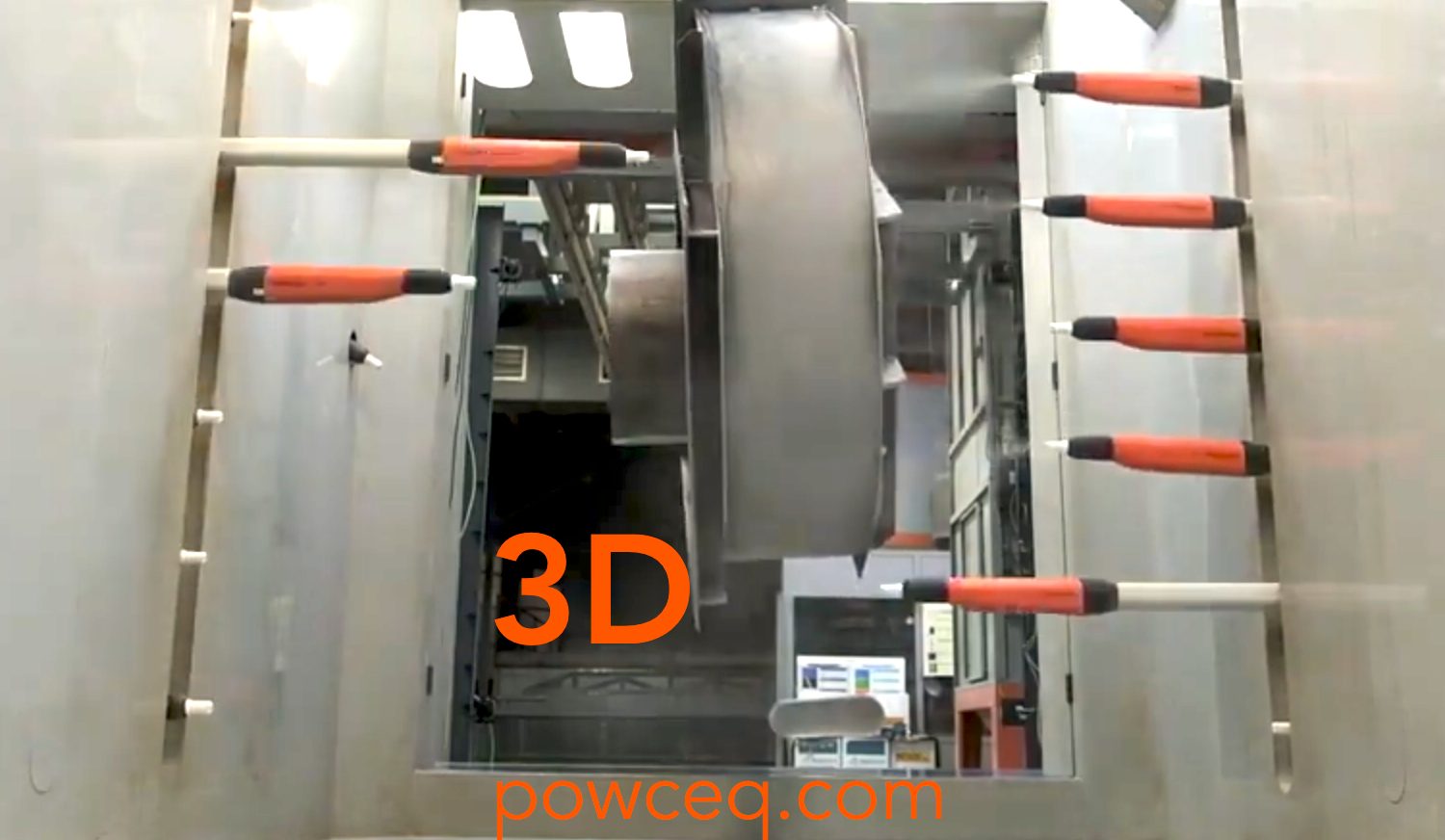

Innovative, 3D scanners are used

Shorter delivery times by months

Since 2010

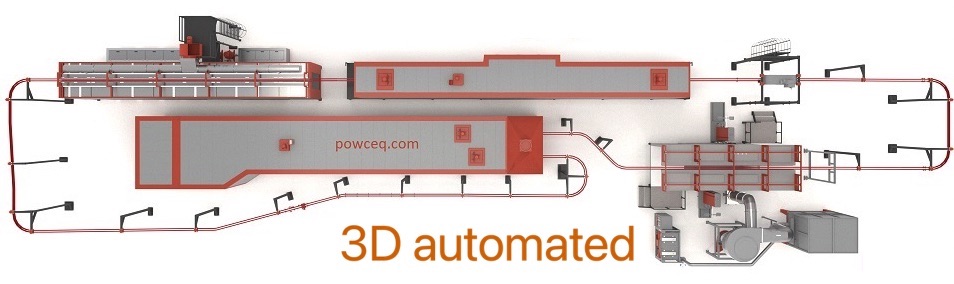

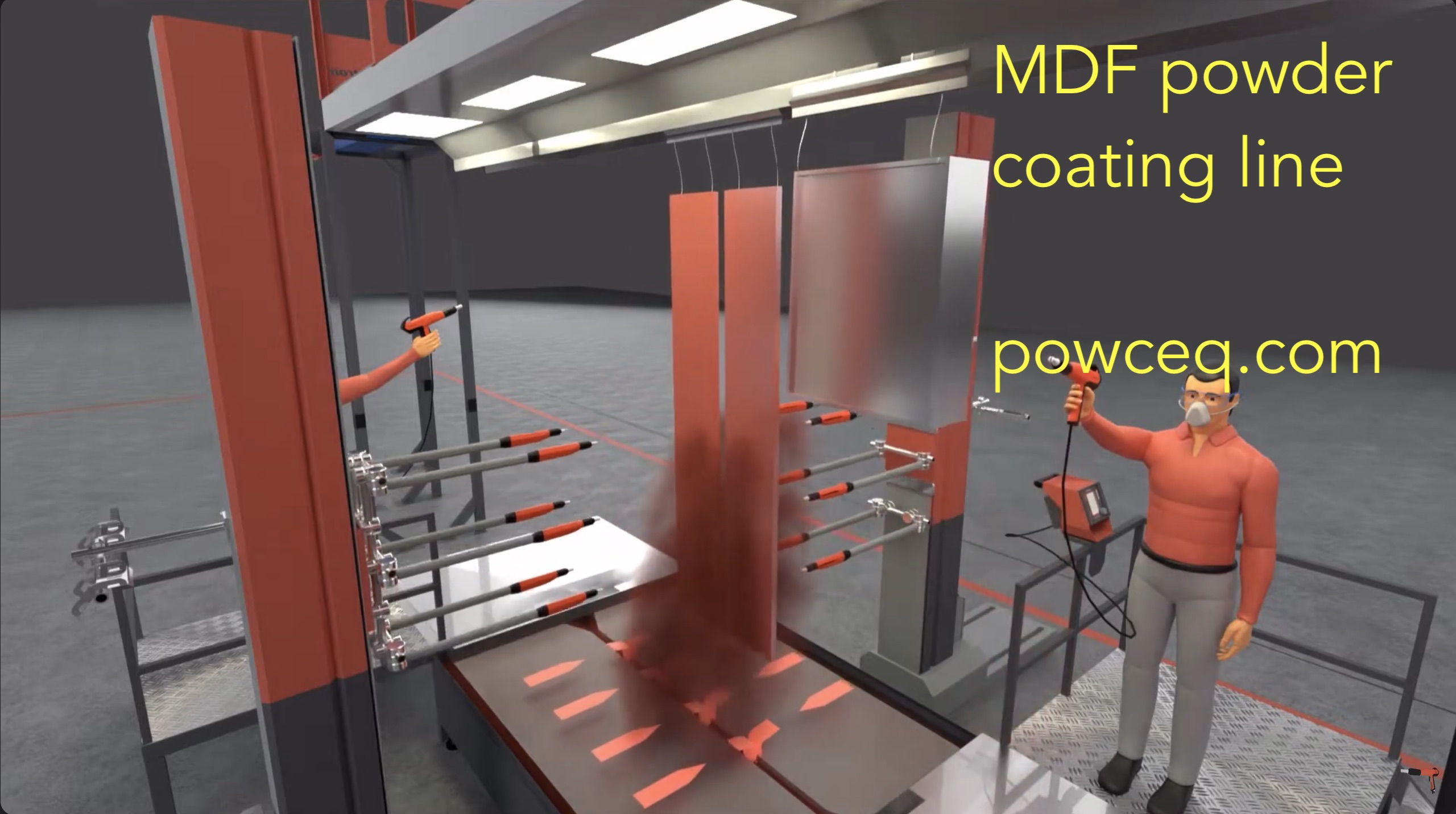

Automated industrial powder coating systems

Automated industrial powder coating systems

In addition to the spray gun, a powder coating system will also include a powder feed system and a control unit. The powder feed system delivers the powder from the hopper to the spray gun, while the control unit regulates the flow of powder and controls the electrostatic charge.

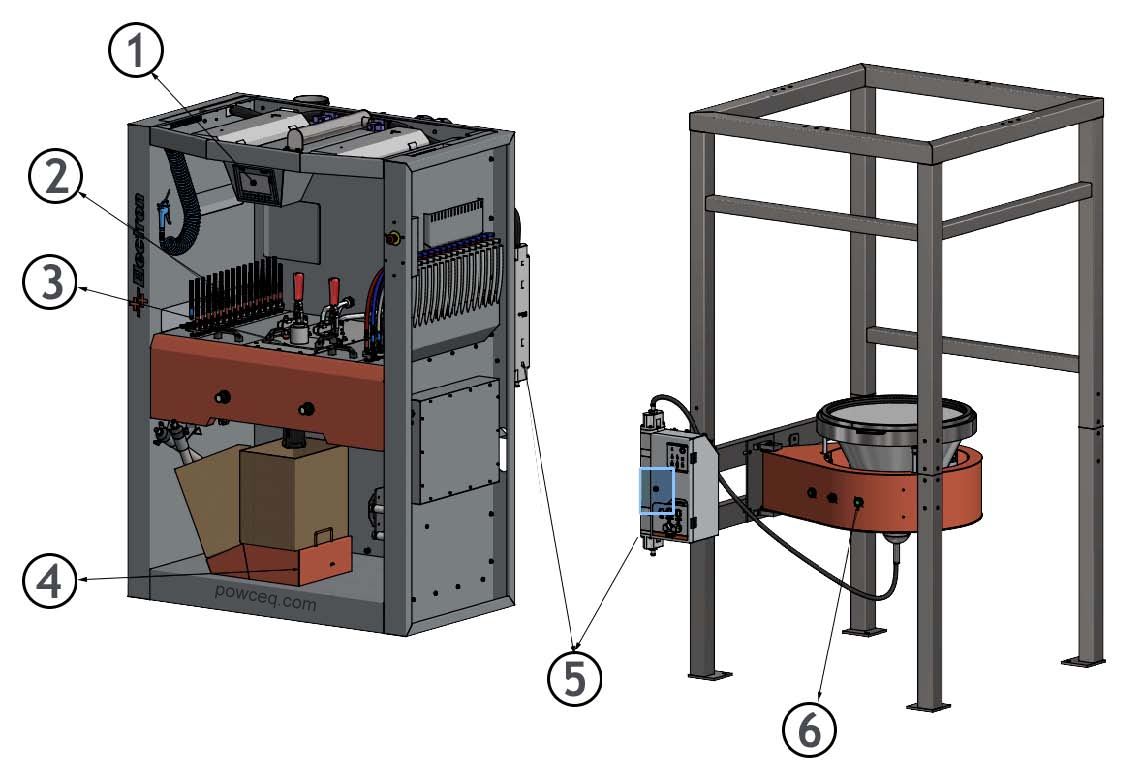

Powder center

Powder center

Powder feed center

6 Variations

Reduces powder consumption and cleaning time

PLC controlled

Pump system

Transfer Pump

High Efficiency

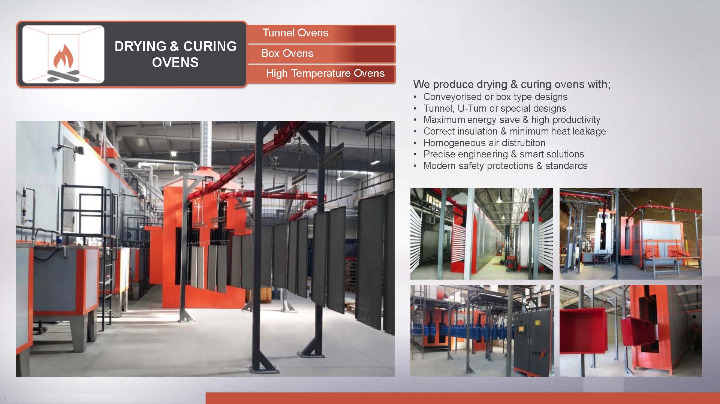

After the powder has been applied, it must be cured using heat. Curing ovens are used to heat cure parts after they have been coated with powder. These ovens come in various sizes and can be powered by electricity or gas. The size of the oven needed will depend on the size of the parts being coated and the volume of production.

Powder curing oven

Powder curing oven

Box type electrical or gas / oil heated

Subsidized or box-shaped designs

Energy-efficient and productive

Perfect insulation and minimal heat loss

Homogeneous air distribution

Continuous ovens

Tunnel

U-Turn or special designs

Precise technology & intelligent solutions

Other equipment that may be used in a powder coating system includes booths, conveyors, washers, and dryers. Booths are used to contain overspray and prevent contamination, while conveyors are used to move parts through the system. Washers and dryers are used to clean and prepare parts before coating.

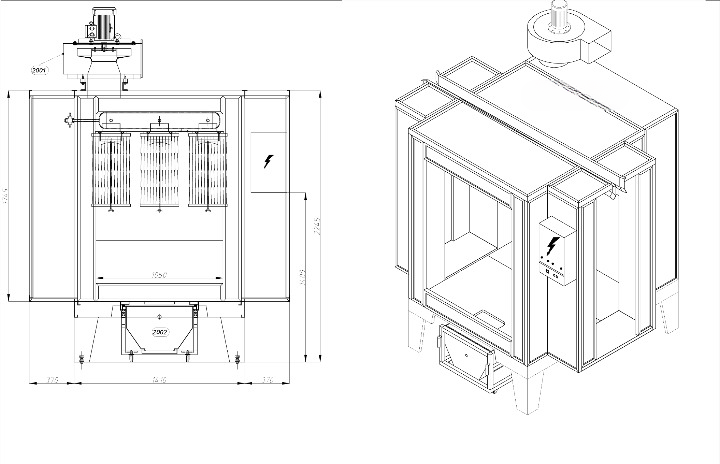

Powder booths

Powder booths

Manual powder booth

Filter or recycling

Cyclone or filter with recovery

- Made of plastic or steel

- Quick color change

- Low-noise fans

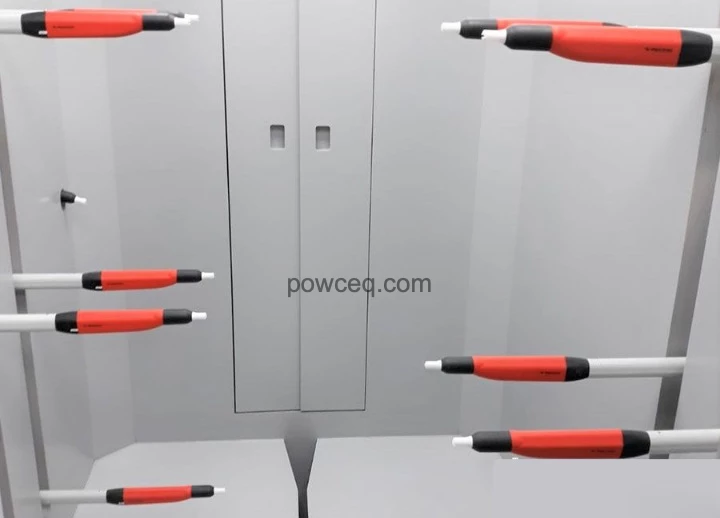

Automatic powder booth

Automatic powder booth

Control units

Reciporators

3D Scanners

- Power & Free or Axial

- Automatic or manual

- Optimal solutions according to customer requirements

- High quality standards

Pretreatment lines

Pretreatment lines

Nano technology (Oxsilan, phosphating)

• Degreasing and pickling

• Iron and zinc phosphating lines

• Without chrome

• Spraying & immersion

• Savings in chemical and water consumption

Overall, having the right equipment is essential for achieving a high-quality powder-coated finish. From spray guns and control units to curing ovens and booths, there is a wide range of equipment available to meet the needs of any powder coating operation.

Automated powder coating is a process that involves the application of a dry powder to a surface using specialized equipment. The powder is typically applied electrostatically and then cured under heat to form a hard, durable finish. This type of coating is commonly used on metal products, such as appliances, automotive parts, and outdoor furniture.

One of the key advantages of automated powder coating is its efficiency. The process can be fully automated, allowing for high levels of productivity and consistent quality. The use of specialized equipment also ensures that the powder is applied evenly and in the correct thickness, reducing the need for touch-ups or rework.

Powder Coating Equipment & Machine for sale

Worldwide easy delivery - new systems

Offers

receive password immediately

Info sheets PDF

No password required

Description and presentations

Documents

No password required

Product Summary

~ We ship anywhere, worldwide

Manual or automatic powder coat spray guns

Powder centers and powder transfer pumps

Powder coating booths, Fast color change booths

Dryer, Oven

Pretreatment lines - automatic washing

Special solutions

Nr.1 Coating gun: Pro M

Nr.1 Coating gun: Pro M Nr.2 Coating gun: Master M

Nr.2 Coating gun: Master M Nr.3 Booth FT2 & oven EL15

Nr.3 Booth FT2 & oven EL15 Nr.4 Booth FT3

Nr.4 Booth FT3 Nr.6 Oven electrical E3

Nr.6 Oven electrical E3 Nr.7 Oven gas G4

Nr.7 Oven gas G4 Automated Plant

Automated Plant User manual spray guns

User manual spray guns User manual booth

User manual booth User manual oven

User manual oven Atex-Certificate

Atex-Certificate Dimensions booths

Dimensions booths