Product Summary

~ We ship anywhere, worldwide

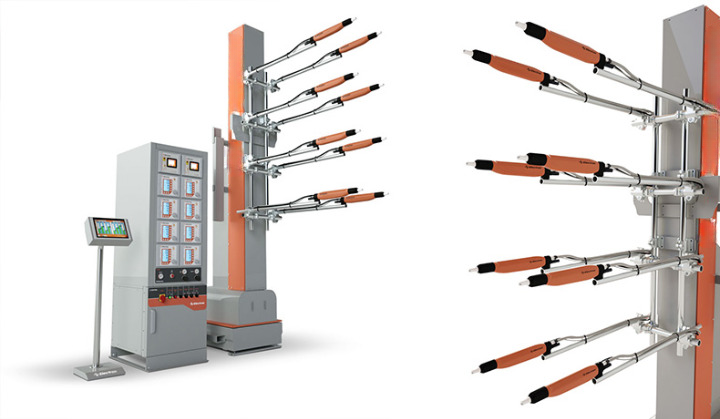

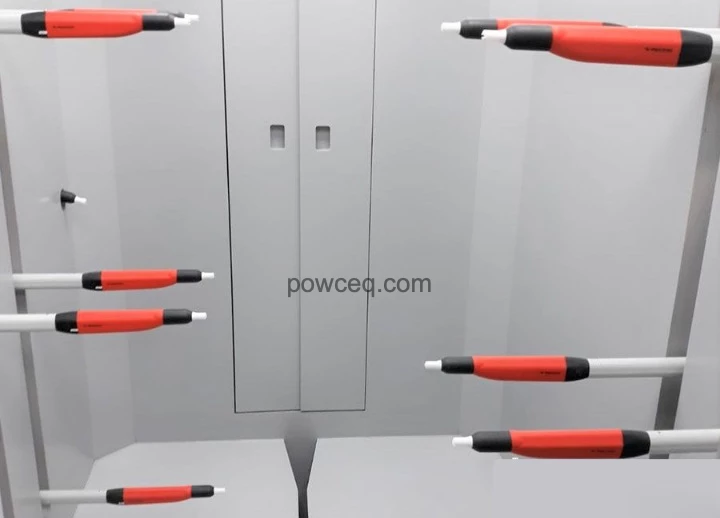

Manual or automatic powder coat spray guns

Powder centers and powder transfer pumps

Powder coating booths, Fast color change booths

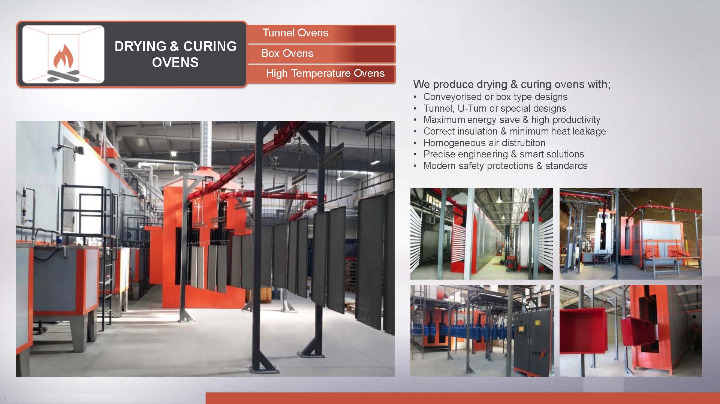

Dryer, Oven

Pretreatment lines - automatic washing

Special solutions

From the idea to commissioning

Procedure: (duration approx. 3 to 5 months)

Idea - Project planning - 3D drawing - Inspection of reference sites

Contract - Production - Delivery - Installation - Commissioning - Training

Non-binding recommendation of coating powder and pre-treatment chemistry

Produced and developed in our own factory

Several in-house installation teams, most with 15 years of experience, get to work immediately after delivery.

Non-binding & uncomplicated in 3D

Our local team will be happy to assist you.

Several reference systems can be viewed in Switzerland, Germany and Austria.

Whether in New Zealand, South Africa or the USA, we already have systems in operation in 83 countries!

Application of powdercoat

Small powder coating booth

Manual booths

Manual booths

Filter or recovery

Manual powder coating setup

Manual powder coating setup

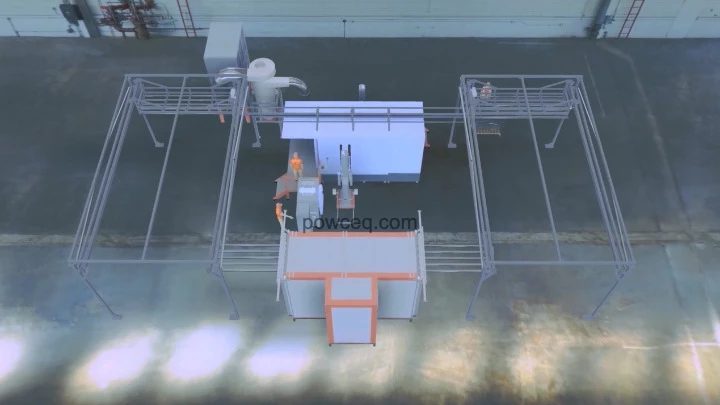

Spray booth

+ curing oven

+ Powder equipment

+ rail system as required

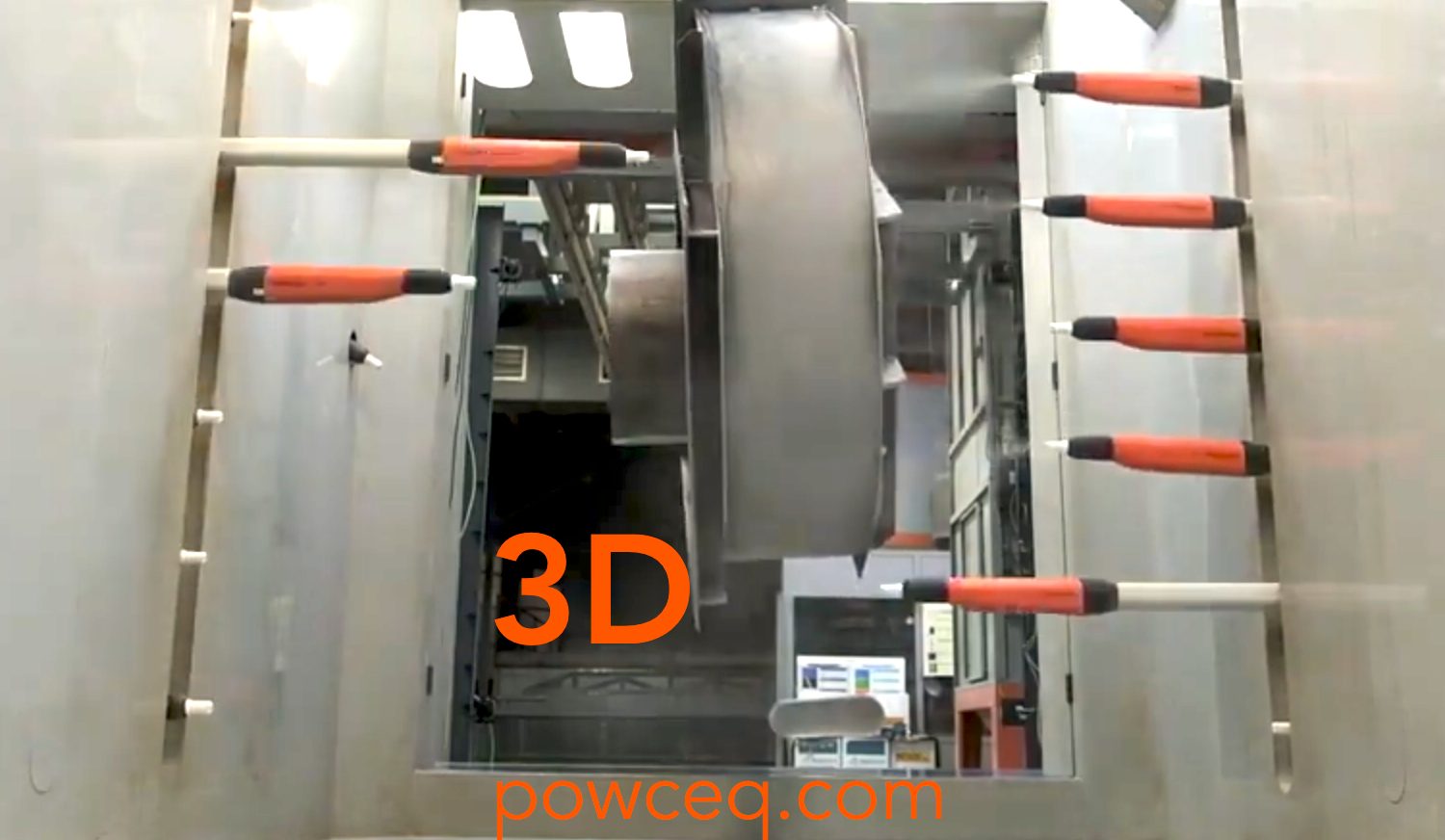

Booth for automatic powder coating

Booth for automatic powder coating

- Steel, plastic or hybrid, fast color change

- Power & Free or Axial

- Customized solutions

- Tunnel, U-Turn or special design

- Precise technology & intelligent solutions

Booths for fast color change

Booths for fast color change

Continuous pretreatment lines

Continuous pretreatment lines

- Nano technology (oxsilane, phosphating, degreasing

- Degreasing and pickling

- Iron and zinc phosphating line

- without chrome

- Spraying & dipping pre-treatment lines

- Savings in chemical and water consumption

Powder coating curing ovens

Powder coating curing ovens