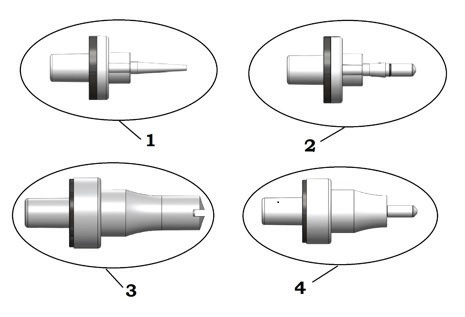

Nozzles and accessories for powder coating spray guns

Replacement parts with codes and pictures

Gema

Wagner

Nordson

Choose spare parts list below

Choose brand for non-original spare parts

Choose brand for non-original spare parts

Gema Powder Coating Gun - Spare Parts

- 1000049 – Flat jet nozzle (Profiles - Standard nozzle)

- 1000055 – Electrode holder flat

- 1000047 – Flat jet nozzle set

- 378518 – Round jet nozzle

- 382914 – Electrode holder round

- 382922 – Round jet nozzle set

- 379611 – Nozzle set - Round jet

Here are the top 10 most frequently required spare parts for Gema powder coating guns, based on industry consensus and replacement trends:

1. Nozzles (flat & round jets) – Control spray pattern; most common wear part

2. Electrode holders – Secure the high-voltage electrodes; replaced often alongside nozzles

3. Injectors / Venturi tubes – Critical for powder fluidization and chimney wear-prone

4. O-rings and seals – Ensure airtight connections in hoses and injectors

5. Deflectors / air caps – Shape airflow, smooth wear areas

6. Powder hoses & tubing – Constant abrasion from powder; need regular replacement

7. Insert sleeves (Teflon/Tefzel) – Wear inside fluidizing pump; commonly replaced

8. Cascade – Connects gun body to injector; occasional wear/damage

9. Gun body components (back cover, trigger, cable) – Structural or control wear parts

10. Control module / HV contact ring – Electrical components that can degrade; replaced in severe cases

Why These Matter • Nozzles, electrode holders and injectors are closest to powder flow and high-voltage currents—major wear zones. • O-rings, sleeves, hoses safeguard airtightness and powder movement; these wear steadily with use. • Deflectors, cascades, and modules support spray quality and electrical integrity over time.