Powder Coating Machine price in UAE

In average, professional powder coating machines or so-called electrostatic spray guns cost in average about 12.000 AED in its basic delivery.

Adding a vibration table instead of a container or touchscreen will undoubtedly increase its price.

What is the real difference in quality and price?

The powder coating machine charges the powder particles, causing them to adhere to the grounded surface. The design, hardware, and quality of used components all make a difference in the results. The efficiency of the product varies from 60 to 85%, with top brands only reaching 85%. Calculated on time and powder, this makes a big difference in running cost.

Welcome to our Engineering Company. Founded in 2010

Any type available

Variations including pump system

Accessories

Corona ring + Quick cleaning module

5 main types of powder coating guns

- Analog control

- Digital or touchscreen

- Pump feeding system

- Cup gun / case set

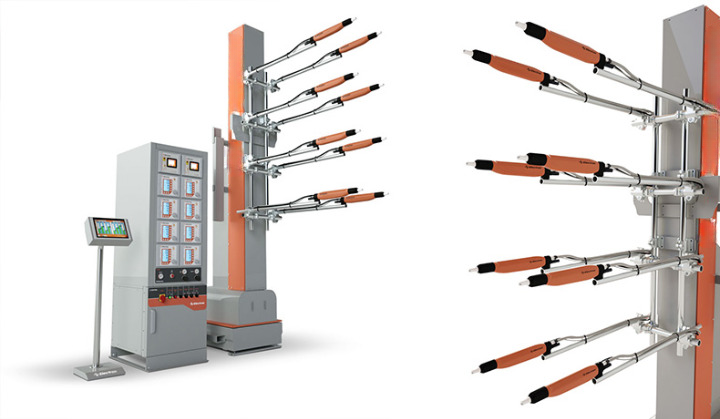

- Automatic spray gun

Please check brochure below for all versions

Major Brands & Accessories

Gema — Trolleys & Spare Parts

Wagner — Vibrating Tables

Nordson — Containers & Kits

Top brands available

Vibrating table for cartons

50 Liter container

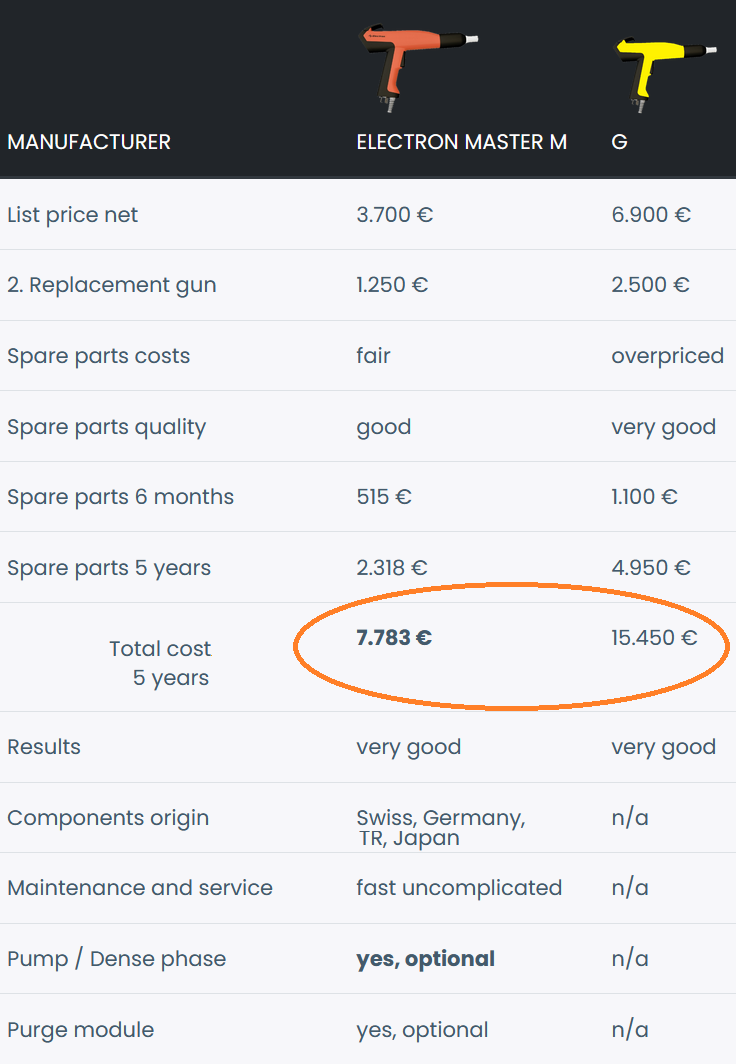

Powder Coating Gun Comparison

Performance Tests & Analysis

“Coat Like a Master!” Explained

Powder coating guns test

or

or  ?

?

Why spend twice as much when it delivers just as high quality results?

Don't waste time and money! Coat like a Master .

Brochure powder coating equipment

Choosing the Right powder coating machine

Powder Delivery Systems Explained

Control Settings: kV / µA Guide

Durability & Build Quality Factors

Powder coating is a popular finishing technique that involves the application of a dry powder to a surface. The powder is then cured using heat to form a hard, durable coating. Powder coating guns are essential tools for this process, as they allow for the precise and even application of the powder.

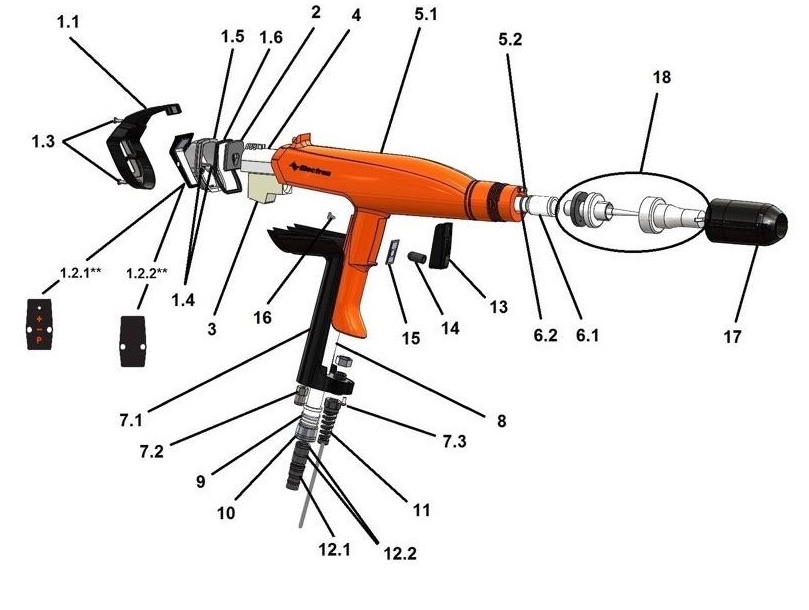

When choosing a powder coating gun, there are several important factors to consider. These include the type of gun, the powder delivery system, the control system, and the overall quality and durability of the gun.

There are two main types of powder coating guns: corona and tribo. Corona guns use an electrostatic charge to attract the powder to the surface being coated. Tribo guns, on the other hand, use friction to charge the powder particles. Each type has its own advantages and disadvantages, so it’s important to carefully consider which type will best suit your needs.

The powder delivery system is another important consideration. This refers to how the powder is fed into the gun and onto the surface being coated. Some guns use a fluidized bed system, while others use a box feeder or a hopper. Each system has its own advantages and disadvantages, so it’s important to choose one that will work well for your specific needs.

The control system is also an important factor to consider. This refers to how the gun is operated and how the various settings can be adjusted. Some guns have simple controls with only a few settings, while others have more advanced controls with many different options. It’s important to choose a gun with a control system that is easy to use and allows for precise adjustments.

Finally, it’s important to consider the overall quality and durability of the gun. A high-quality gun will be well-built and able to withstand regular use without breaking down or malfunctioning. It’s also important to choose a gun from a reputable manufacturer with a good track record of producing reliable and durable products.

In summary, when choosing a powder coating gun, it’s important to carefully consider the type of gun, the powder delivery system, the control system, and the overall quality and durability of the gun. By taking these factors into account, you can choose a gun that will meet your needs and provide reliable performance for years to come.

Need to coat with even more efficiency and powder amount? Check out our new Dense phase pump feeding powder coating gun