Pretreatment process before powder coating

Spraying or dipping processes are optimally designed

Whether black steel MS, carbon steel, iron, aluminum or galvanized workpieces, with us you clean efficiently and energy-saving.

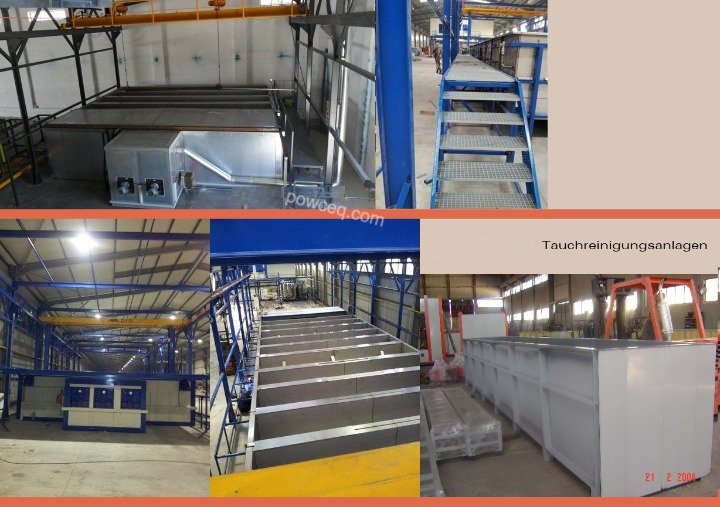

We provide complete solution, including tanks, chemical, side-walk, cranes with automatic movement

Chamber washing systems

Types of pretreatment applications

- Spray and dip pretreatment lines

- Nanotechnology (Oxsilane, Bonderite)

- Degreasing, wash oil in 10min

- Phosphating, improve adhesion and enhance its corrosion resistance

- Chrome free cleaning

Immersion cleaning systems, Dip tank pre-treatment with chemicals before powder coating

In-line continuous spray washing

Advantages of pretreatment applications

- Maximum energy saving

- Minimal chemical and water consumption

- Nano pretreatment