Vertical powder coating line for aluminium profiles

Less space - more quantity

Power & Free automation 5m/min

This technique is particularly suitable for coating a large number of small to medium-sized parts with powder coatings in a short time.

- Nano pre-treatment or sandblasting

- Dryer

- Detection system

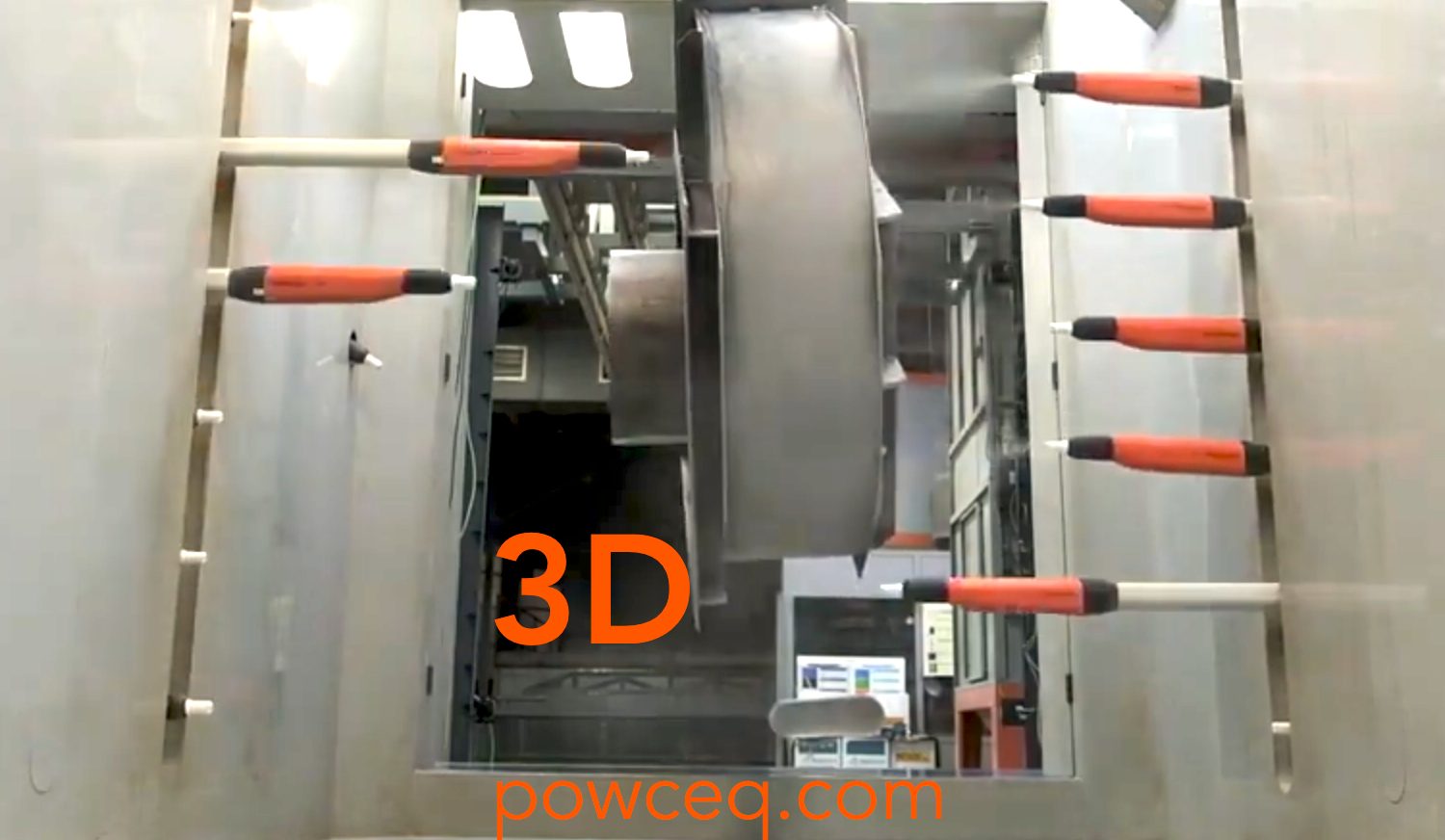

- Plastic booth

- Automatic spray guns

- Powder center

- Curing oven

Latest technology increases profit

Buy better quality, do not need to invest again in 3 years

Drying and curing ovens

Perfect insulation and minimal heat loss

Uniform air distribution

Precise technology & intelligent solutions

Conveyor systems

Power & Free or Axial

Recovery plastic booths

Cyclone or filter with recovery

Made of plastic or steel or hybrid

Quick color change

Low noise fans

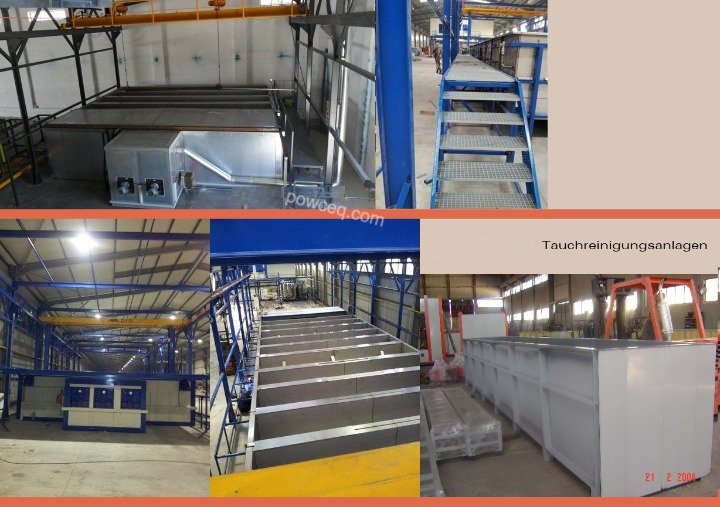

Automated dipping or spray pretreatment

Aluminium & Galvanized Sheet

Pretreatment for aluminium profiles, particularly for powder coating (e.g., to meet Qualicoat or GSB standards), typically involves a multi-stage process, with 5 to 8 stages being the most common in industrial applications to ensure durability and corrosion resistance.

The goal of these stages is to remove surface contaminants (oils, dirt), remove the natural oxide layer (etching), and apply a conversion coating (chrome or chrome-free).

Standard 5-Stage Process

A common, high-quality 5-stage setup for aluminum includes:

- Cleaner/Degreaser: Removes dirt, oil, and grease.

- Rinse: Removes residual cleaner.

- Etch or Acid Pickling: Removes the natural oxide layer and creates a uniform surface.

- Rinse: Removes etching byproducts.

- Conversion Coating: Applies a corrosion-resistant layer (chromium-free/zirconium or chrome).

Note: A final DI (Deionized) water rinse is crucial to prevent contamination before drying.

6 to 8+ Stage Processes (Enhanced)

For higher performance requirements, especially in harsh or coastal environments, more stages are added to ensure thorough rinsing and better chemical deposition:

- 6-Stage: Often includes additional rinses (e.g., Cleaner, Rinse, Etch, Rinse, De-smut, Conversion Coating).

- 7 to 8 Stages: Adds extra rinses (like Reverse Osmosis rinse) and specialized sealers (e.g., chrome-free zirconium seal).

Typical Steps Overview

- Cleaning: Alkaline degreasing.

- Etching/Pickling: Acidic etching to create a matte finish.

- Desmutting: Removing residue from the etching process.

- Conversion Coating: Applying a protective layer (Chromate or Chrome-free).

- Rinsing: Crucial water rinses (tap water followed by DI water) between every chemical step.

- Drying: Hot air oven to ensure no moisture remains before powder application.

Proper pretreatment ensures the powder adheres firmly to the aluminium and meets industry standards like AAMA 2605 or Qualicoat for long-term, corrosion-resistant, and aesthetically pleasing results.

Several manufacturers in benefit of clients

- Process optimization right from the start

- Highly modern automation

- Hanging workpieces with robots*

- Cost reduction, quality improvement

View reference sites

Switzerland, Germany, Austria and Europe-wide

USA, UAE & GCC

Optimal choice of devices

Gema, Nordson or Wagner Powder coating systems

Why should you work with us?

Engineering office started in Germany 2010, worldwide experienced

Multiple manufacturers for the benefit of customers

Multiple internationally mobilized teams

Shorter delivery times by months

Highly modern, efficient, turnkey

Steel / plastic cabins with cyclone separator

Automatic powder booths

Plastic powder booths