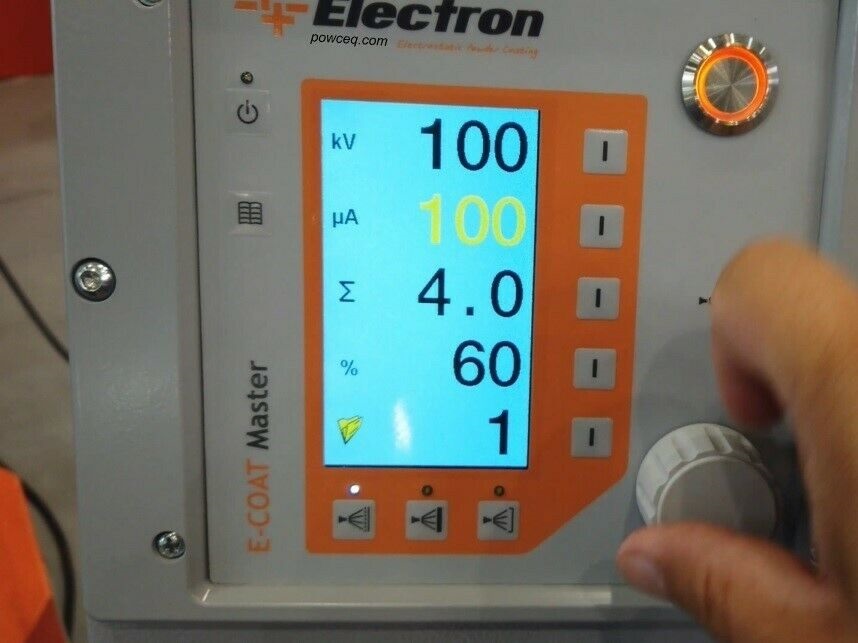

Correct powder gun setting

Here is our new 2025 spray gun with 4 patents ! (in blue)

Quick keys

Generally with E=4 and % 60

3 quick keys for recipes (under the display)

Flat parts

Second layer

Complicated shapes

Understanding parameters

- kV = high voltage in kiloVolt, static friction

- µA = spray current in microamps

- E = total air = 4.0 Nm 3 / h (h = hour)

- % = Powder output rate, for example 60% coating 40% air

- Recipe # 3

kV - µA Relation

Automatic regulation of the load to the distance workpiece

Control unit recognizes the distance or workpiece surface and regulates kV and µA at that moment. If the gun tip is too close, the µA is reduced and vice versa.

High kV if:

The higher the setting, the stronger the charge / adhesion.

flat parts and for the outside of box-like parts.

Low kV if:

the more detailed and complex the part (inner surface) to improve transfer efficiency so that it penetrates to the corners

(more powder particles to the part) e.g.

- 50 kV with 20 to 40µA

- 50 to 60 air mixture %.

- increase the distance between the gun and the part

- to obtain a very uniform coverage on flat surfaces

1. Flat parts

Flat or first layer

100 kV / 100 µA set.

Recommended set area is 50 to 80 kV with 70 to 100 µA

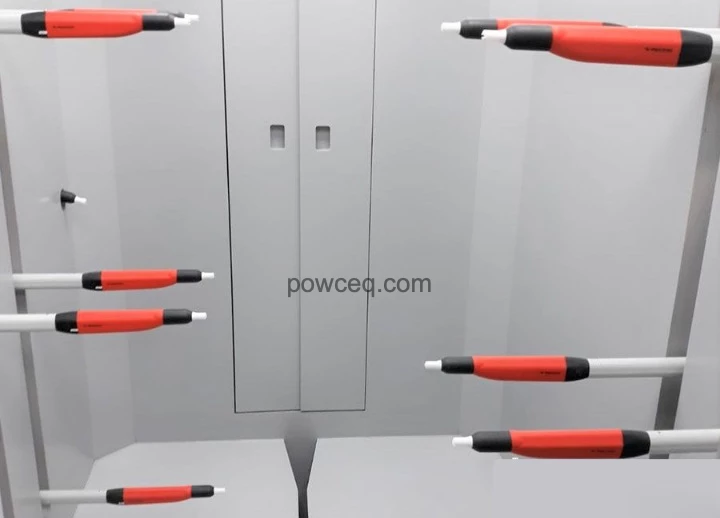

3. Complicated shapes

Square edged workpieces: (outer surface)

100 kV / 22 µA set.

Works well with 90 kV and 22-35 µA

2. Overcoating or second layer / two-coat process

100 kV / 10 µA set.

Coating Gun Setting values

Coating angular workpieces

kV 90 = 90,000 V

µA 35 = 3.5 x 10-5 A

E 4.0 Nm3/h or lt/min

% 60 = powder output

- = powder coating in spray air

Recipe no. 3

2. Overcoating or second layer / two-coat process

100 kV / 10 µA set.

The range of values for the second layer fluctuates between

- 100 kV with 10 µA and

- 80 kV with 10 µA

- 50 kV with 20 µA, even up to

- 20 kV with 30 µA

- First coating, for example, you can leave the KV setting at 80 kV

- second over-coating at 50 kV

- third over-coating at 30 µA, each with a limit of 10 to 30 µA.

If you notice reionisation, i.e. the inner corners are already electrostatically charged so that no further penetration of the powder is possible, you can reduce the KV and leave the microampere setting at the lower end of the range of 10 to 30 µA microamps.

Two-shift process doesn't work? More Tips

Here are a few tips

Sometimes important rules are overlooked.

Possibly increase the % of powder used.

1. Use the earthing tester

First layer 4 millimeters thick? Create a bare metal point on the part so that it can be grounded

2. Check powder coating values on manufacturers box

3. Does the first coat have stains, problems with significant peeling or rust breakage?

4. Cleaning the product surface

Powder Coating Equipment & Machine for sale

Worldwide easy delivery - new systems

Offers

receive password immediately

Info sheets PDF

No password required

Description and presentations

Documents

No password required

Product summary powder coating equipment

Click below on interested product ~ We ship anywhere, worldwide

Nr.1 Coating gun: Pro M

Nr.1 Coating gun: Pro M Nr.2 Coating gun: Master M

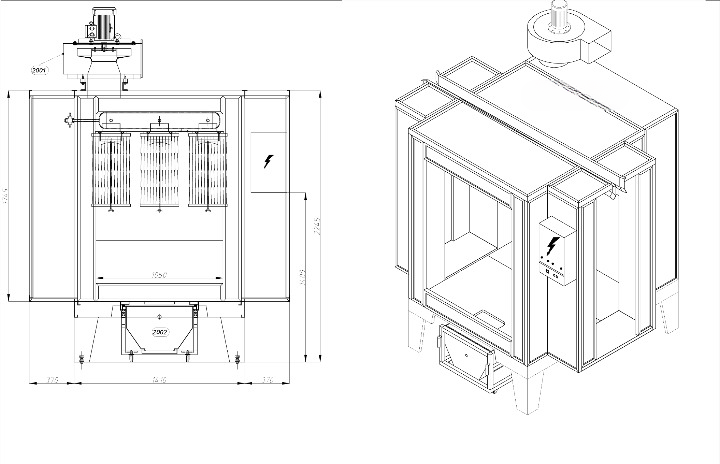

Nr.2 Coating gun: Master M Nr.3 Booth FT2 & oven EL15

Nr.3 Booth FT2 & oven EL15 Nr.4 Booth FT3

Nr.4 Booth FT3 Nr.5 Booth FT5

Nr.5 Booth FT5 Nr.6 Oven electrical E3

Nr.6 Oven electrical E3 Nr.7 Oven gas G4

Nr.7 Oven gas G4 Automated Plant

Automated Plant Set of small booth + oven + gun

Set of small booth + oven + gun Powder center

Powder center User manual spray guns

User manual spray guns User manual booth

User manual booth User manual oven

User manual oven Atex-Certificate

Atex-Certificate Dimensions booths

Dimensions booths