MDF Board Powder Coating Process

- Why you should start with this innovative process?

- Overview of its stages

- Which equipment do you need?

Powder coating on MDF is now seen as an preferred choice over other alternatives such as laminate veneers and liquid paint.

Low cost one-step finishing process innovation !

20 Minutes only

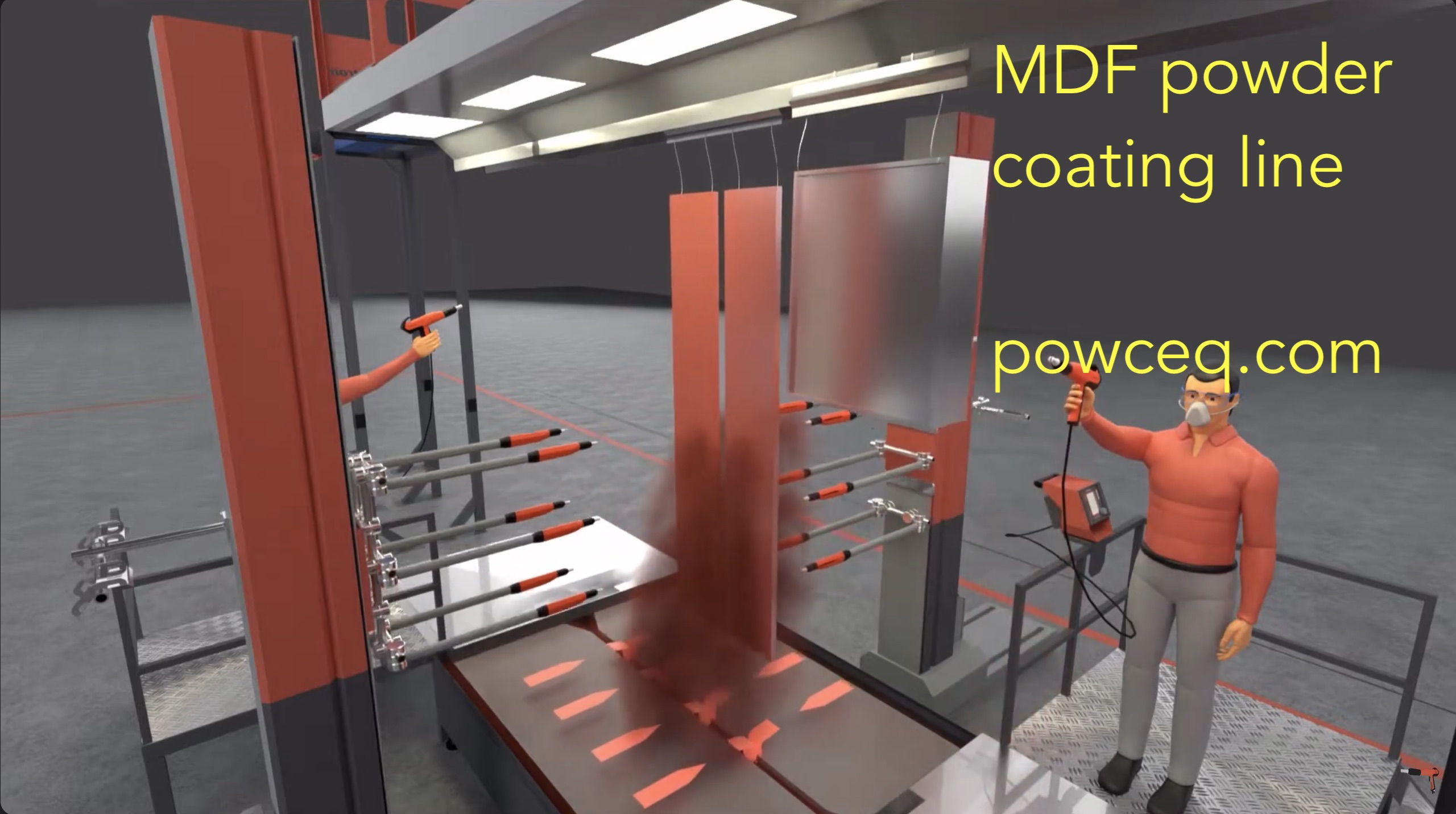

MDF board powder coating line process

Low cure powder coatings needed?

We also supply the special powder coating, get in contact with us !

Application areas are

- Baby rooms

- Panel doors

- Kitchen cabinets

- Bathroom doors

- Office furniture consoles

- TV units

Incredible benefits of coated MDF panels

- Healthy product EN 71-3 (Safety of toys, babies can touch it)

- No solvents, odourless, VOC-free

- Antibacterial, antiallergic

- Scratch durable

- Mechanical endurance

- Improved humidity resistance (Bathroom furniture)

- Complete freedom of design

- Ease of application

- Low cost

- Time saving ! One-step finishing process

- Just few employees do the job easily

- Automated process

- Additionally it is environmentally friendly

But this is now a perception of the past as dramatic improvements of the low cure technology combined with state-of-the-art application techniques are making MDF powder coating today a reality. Accessible to the entire furniture industry.

Stages of MDF powder coating process

MDF board has now been giving is final shape through cutting, routing or drilling.

In the heart of this process, MDF properties are crucial !

- Thickness

- Size

- Density

- Humidity (Moisture) % of panel

- Other properties of panel such as wood type etc.

MDF panels from several suppliers should be tested at beginning.

Preparation and Loading

The boards may need proper sanding and cleaning plus a final check of the boards moisture content is recommended to secure a consistent application over time

Once the boards are properly hung they move along the conveyor system through different stages, follow -->

Preheating

The boards first pass through the preheating oven where are they are subject to approximately

1 - 2 minutes

of surface heating with temperatures of up to

40 to 85°C , in average 70°C / 158°F

depending on thickness and size of the boards

Preheating is a key step in the process the temperature brings out the moisture to the surface of the board which makes the MDF board conductive enough to ensure the powder will stick to the board

Application

After the preheating the boards then pass through an application booth

These are non-conductive booths with corona guns and in their opposite standing conductive panels on either sides which insure an even application of powder coating on the board surface and edges.

Once the powder is applied, the board moves over to the curing oven.

Time and temperature depend on coating line design.

- Which type of oven, kW, distance to panel, air flow...

- How application equipment are adjusted

- Powder coatings of which supplier are used

Curing Oven

Thanks to the low curing properties of the powder coating, the integrity and properties of MDF board are not effected

It takes only 4 - 6 minutes, in average 5 min

at 105°C / 221°F to 130°C / 265°F

in average 120°C / 248°F

to cure totally.

Cooling

The boards then usually pass through a cooling zone

All will be left on conveyor lines on cool down after which they can be offloaded from the conveyor

Touch-ready

The board now looks great and can be touched

Unloading

Unloading and packaging

20 Minutes one-stage process !

FAQ

Questions about thickness, methods, tips and more...

-soon-