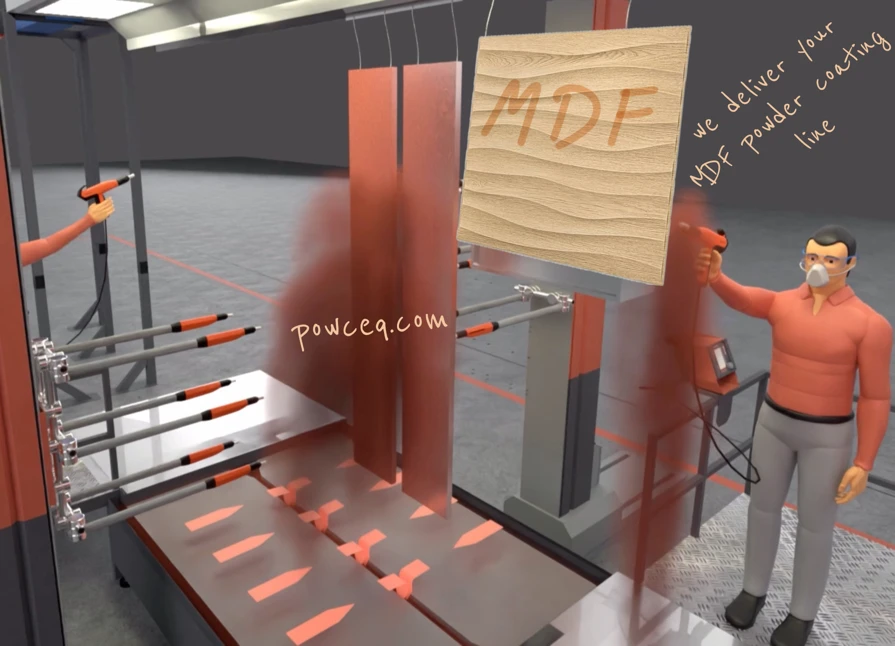

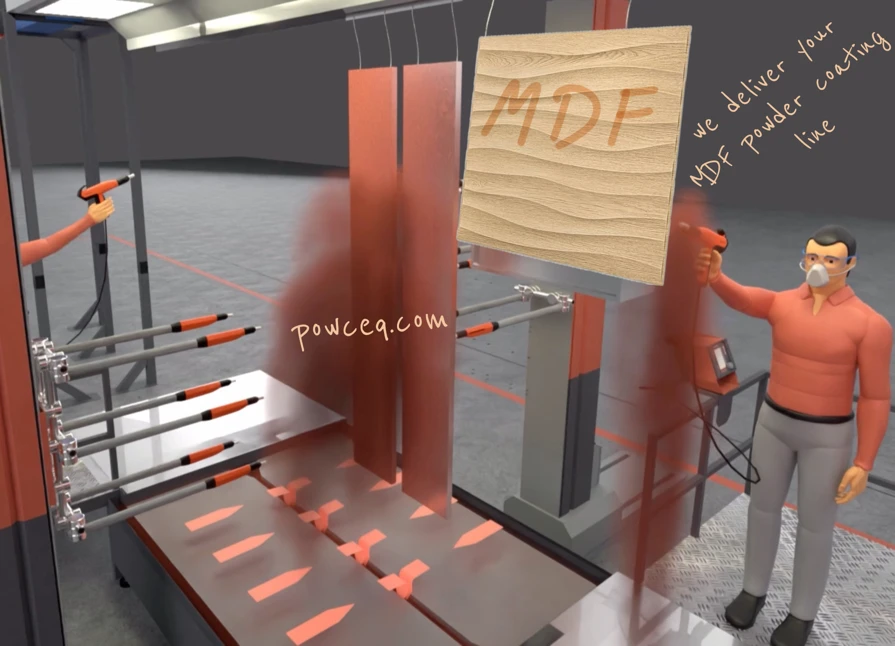

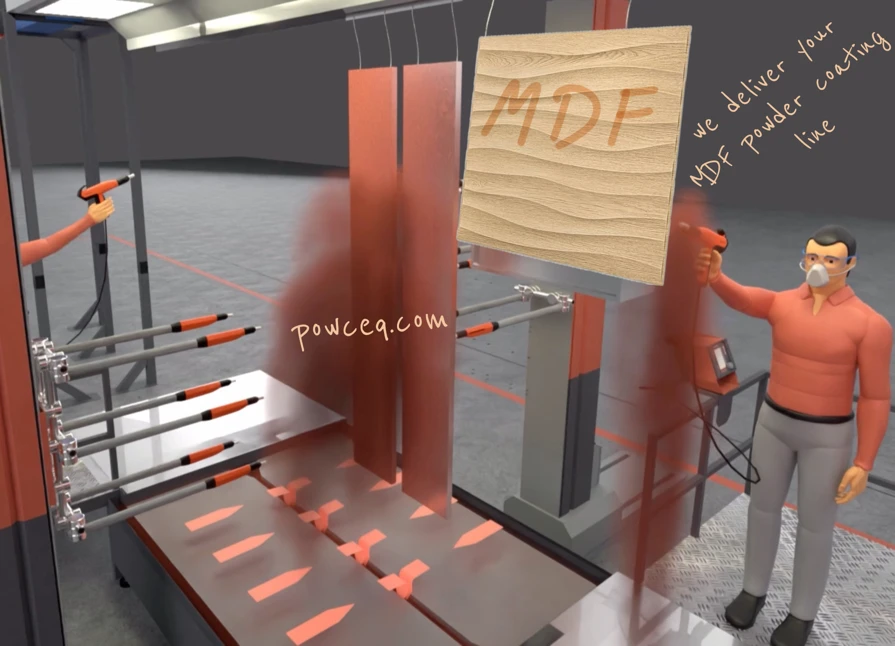

Powder coating on wood

No wood effect, is a coating on wood-based materials such as MDF.

The coated item is

MDF coating line is 50% faster

Finishes that bring the realistic look of wood to your next aluminium or steel project.

The coated item is

Low cost one-step finishing process innovation !

One-step finishing in 20 minutes and is ready ! Some products need two-steps finishing, but is the double time as in other methods.

Best alternative

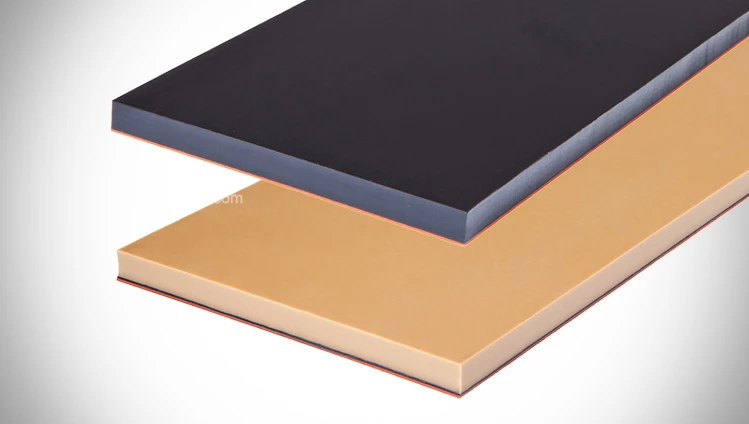

Preferred choice over other alternatives such as laminate veneers and liquid paint.

Application areas are

- Baby rooms

- Panel doors

- Kitchen cabinets

- Bathroom doors

- Office furniture consoles

- TV units

Benefits

- Healthy product EN 71-3 (Safety of toys, babies can touch it)

- No solvents, odourless, VOC-free

- Antibacterial, antiallergic

- Scratch durable

- Mechanical endurance

- Improved humidity resistance (Bathroom furniture)

- Complete freedom of design

- Ease of application

- Low cost

- Time saving ! One-step finishing process

- Just few employees do the job easily

- Automated process

- Additionally it is environmentally friendly

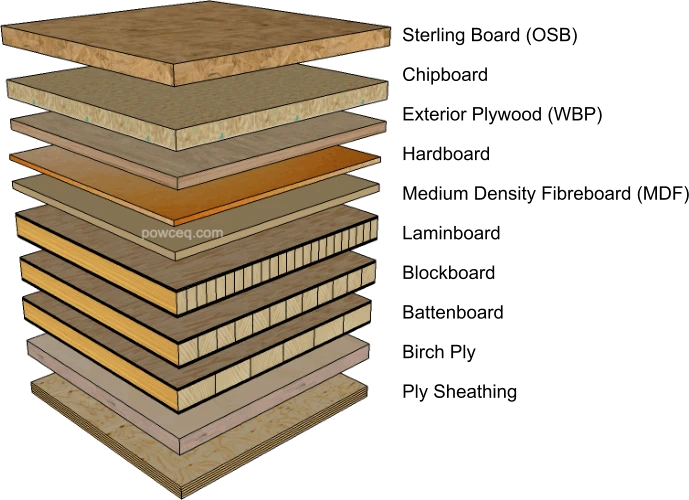

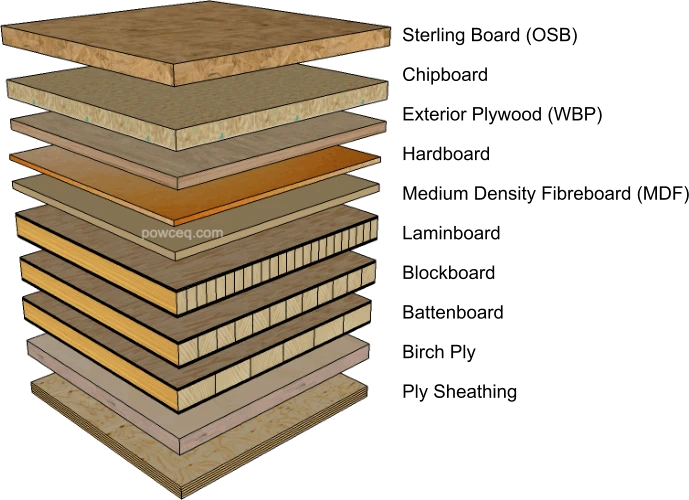

Wooden materials

- Sterling board OSB

- Chipboard

- Exterior Plywood WBP

- Hardboard

- Medium density fibreboard MDF

- Laminboard

- Blockboard

- Battenboard

- Birch Ply

- Ply Sheathing

Some H3

Kitchen cabinets

Colors are limited

Inner 7 x 1.5 x 1.8 m

4m rear heating register

Wardrobe

Kitchen cabinets

Kitchen cabinets

With dividing doors

Temperature

Loading over trolley

Components curing oven

- Control unit

- Control cabinet

- Heating unit

Energysaving

Doors on both sides, loading over trolley

- Control unit

- Control cabinet

- Heating unit

Gas H5

Some powder coating ovens use a gas burner as a heat source. These ovens are often more powerful and can reach higher temperatures than their electric counterparts.

Heating method is critical

- Control unit

- Control cabinet

- lll

DIY H3

Building a DIY powder coating oven sounds to be a cost-effective alternative to purchasing a commercial unit. But in long term cost and security aspect, not recommended.

Safe H4

Safety and efficiency are our top priorities. Our ovens are designed with safety features to prevent accidents and are energy-efficient, helping you save on operating costs.

Contact Us Today H4

Ready to take your powder coating process to the next level? Contact us today to learn more about our powder coating ovens and find the perfect one for your needs.

Advanced H2

With our advanced digital controllers, you can easily set and maintain the desired temperature. This ensures your powder cures properly, resulting in a high-quality finish.

This controller can be an analog device with several probes or a digital PLC.

Importance H3

The temperature in powder coating is crucial as it affects the curing process. Curing is the process where the powder melts and reacts to form a high molecular weight polymer. This polymer provides the coating with its excellent durability and resistance to breakdown.

For Sale H4

Powder coating ovens are available for sale in various sizes and specifications. Some are in stock, others need to be produced which can take several weeks.

Competitive Prices H4

We believe in providing value for money. Our powder coating ovens are competitively priced without compromising on quality or performance.

Price H5

The price of a powder coating oven can vary significantly based on its size, features, and the manufacturer. It's important to consider both the initial cost and the ongoing operating costs when evaluating the price.

Indicative H6

Internal dimensions = working area = maximum workpiece size Length x width x depth = 6 x 1.5 x 1.8 m External dimensions approx. (depending on installation) = 7.7 x 1.8 x 2.15 m

20+ years H2

Is it H3

Frequently asked: Is electric heating cheaper than with a gas burner or oil burner?

Which H3

Independent test results from several powder coating manufacturers are available:

Perfect temperature uniformity

Delivery H3

Optimised production line in the factory

Visits possible by appointment

Powder H4

5x Rail system with transport trolley

Powder H4

Perfect control of the air flow

Homogeneous air distribution

Precise control up to 200°C

Multiple sensors

Digital H4

PLC digital up to 450°C

PLC = programmable logic controller

Controller

The controller is a key component of a powder coating oven. It regulates the temperature and ensures it remains consistent throughout the curing process.

Energy H5

Convection H6

- Electric

- Gas / oil burner, indirect

- Gas direct combustion burner

- Hybrid, heats electric or by indirect burner

Infrared H6

- Electric infrared

- Natural gas catalytic infrared long-wavelength

- Ultraviolet light

Catalytic H3

Integrating an infrared oven to a automatic powder coating line:

Increases production by 50%& Improves product quality Reduces natural gas consumption by 25% annually Achieves a 3-year simple payback

FAQ - Questions & answers about H4

H2 for sale

Offer and price H3

Design and quality H4

Perfect temperature uniformity

Delivery and start-up h5

Optimised production line in the factory

Faster delivery

Installation by our technicians

Product Summary h6

~ We ship anywhere, worldwide

Manual or automatic powder coat spray guns

Powder centers and powder transfer pumps

Powder coating booths, Fast color change booths

Dryer, Oven

Pretreatment lines - automatic washing

Special solutions