Welcome to Our Powder Coating Oven Collection

Curing ovens are used to heat cure parts after they have been coated with powder. In various sizes & combinations

Batch oven

Standard sizes are price competitive and faster to produce. (special dimensions available)

Length 1 to 7 meter / 3 to 23ft

Please check dimensions at below table.

See our offer page here to get your price.

Industrial conveyor oven powder coating

At any dimension, will be delivered turnkey.

Industrial conveyor oven powder coating is a transformative process in the manufacturing industry.

The coated item is then passed through a conveyor oven, where the heat causes the powder to melt, flow, and form a smooth, durable finish.

This method offers several advantages over traditional coating techniques. Firstly, it eliminates the need for solvents, reducing VOC emissions and making the process more environmentally friendly. Secondly, the powder coating provides a uniform, durable, and high-quality finish that is resistant to scratching, chipping, and fading. Moreover, the conveyor oven system allows for continuous, high-volume production, increasing efficiency and reducing costs.

Discover the perfect powder coating oven for your needs right here. We offer a wide range of high-quality, reliable, and efficient ovens designed for optimal powder coating applications.

Why Choose Our Powder Coating Ovens?

Our powder coating ovens are designed with the user in mind. They are easy to operate, maintain, and provide consistent results. With our ovens, you can achieve a smooth, hard finish that is resistant to wear and tear, improving the longevity and aesthetics of your metal objects.

High-Quality Construction

Our ovens are built to last. They feature robust construction, high-quality insulation, and efficient heating elements. This ensures uniform heat distribution for optimal results. One of the best in the market, measured by powder coating powder manufacturers.

Wide Range of Sizes

We understand that every business has unique needs. That's why we offer powder coating ovens in various sizes. Whether you're a small workshop or a large manufacturing plant, we have the right oven for you.

The size of the oven needed will depend on the size of the parts being coated and the volume of production. Smaller ovens are suitable for small- or medium-sized parts and can fit on a benchtop or in a shop corner. Larger ovens are available for industrial-scale production.

Dimensions inside

Usable area in meters

| Type | A width | B height | C depth |

|---|---|---|---|

| EL10 | 1 | 1 | 1 |

| EL12 | 1 | 1,2 | 1,5 |

| EL15 | 1,2 | 1,5 | 1,5 |

| EL20 | 1,5m | 1,8m | 2 |

| EL25 | 1,5m | 1,8m | 2,5 |

| EL30 | 1,5m | 1,8m | 3 |

| EL40 | 1,5m | 1,8m | 4 |

| EL50 | 1,5m | 1,8m | 5 |

| EL60 | 1,5m | 1,8m | 6 |

| EL70 | 1,5m | 1,8m | 7m |

Or any special dimensions

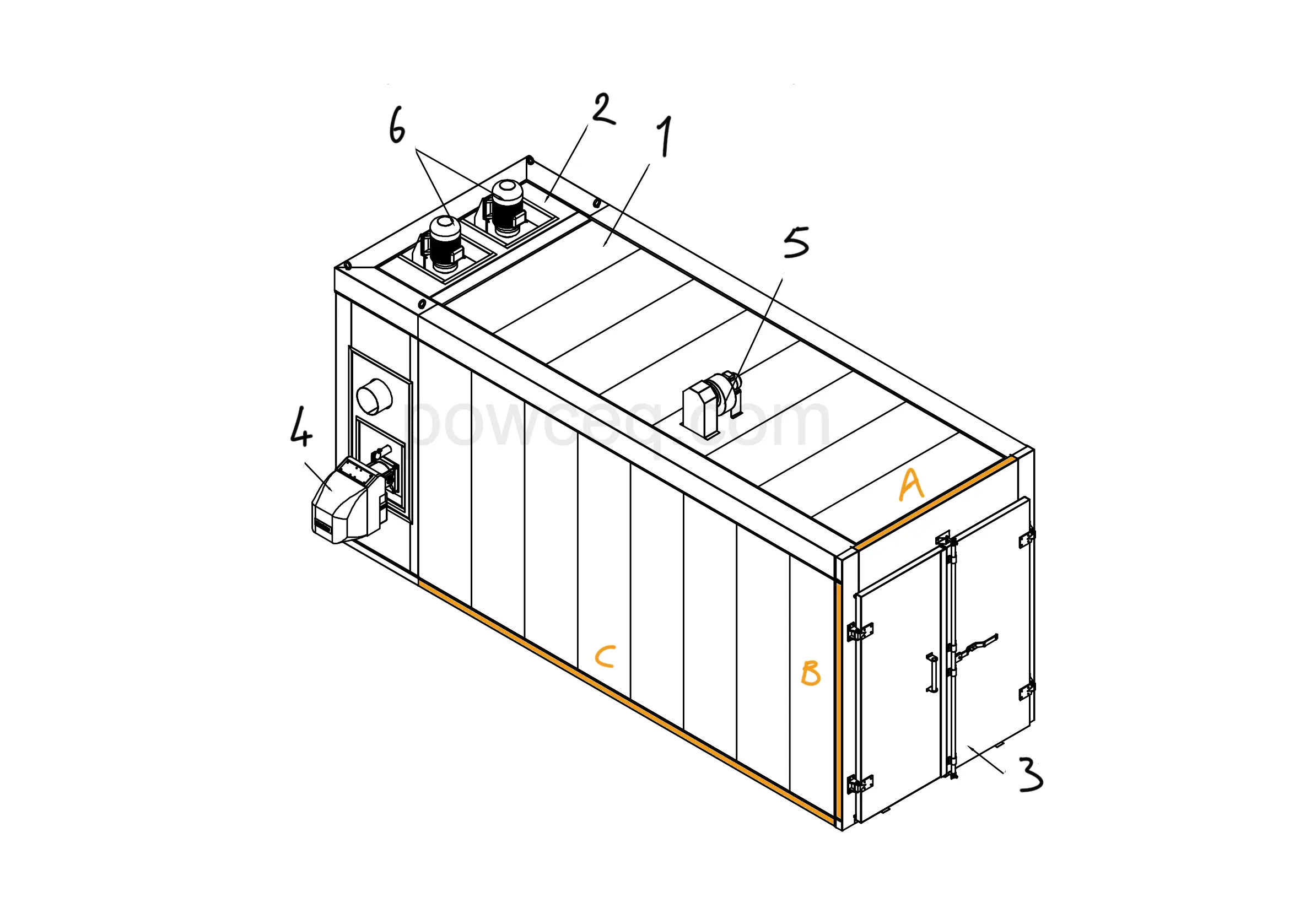

Industrial powdercoat batch oven

- Roof insulation

- Heating unit

- Extra insulated doors

- Gas or oil burner

- Extraction air fan

- Circulation fans

Some standard sizes

The smallest - 1.1m

For 6x rims

Inner 7 x 1.5 x 1.8 m

4m rear heating register

4m side view

3m rear heating register

For trolleys

With dividing doors

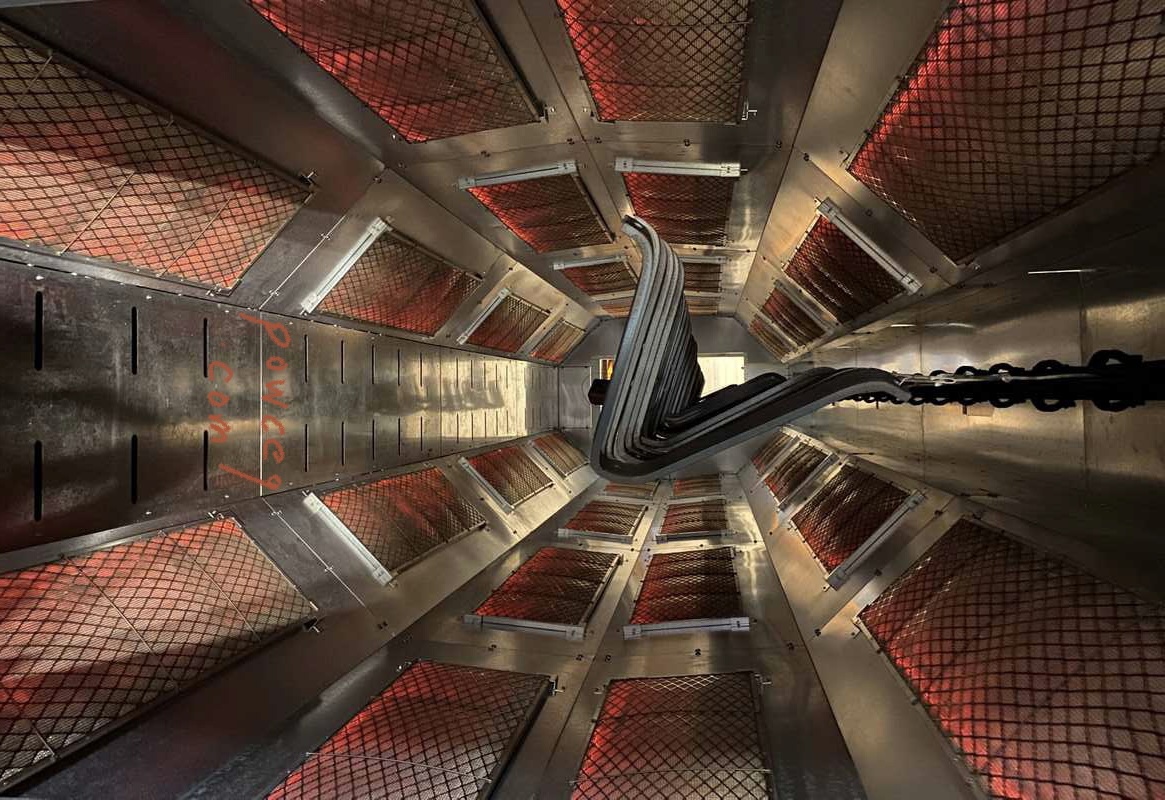

Electric powered heating unit at the rear

Loading over trolley

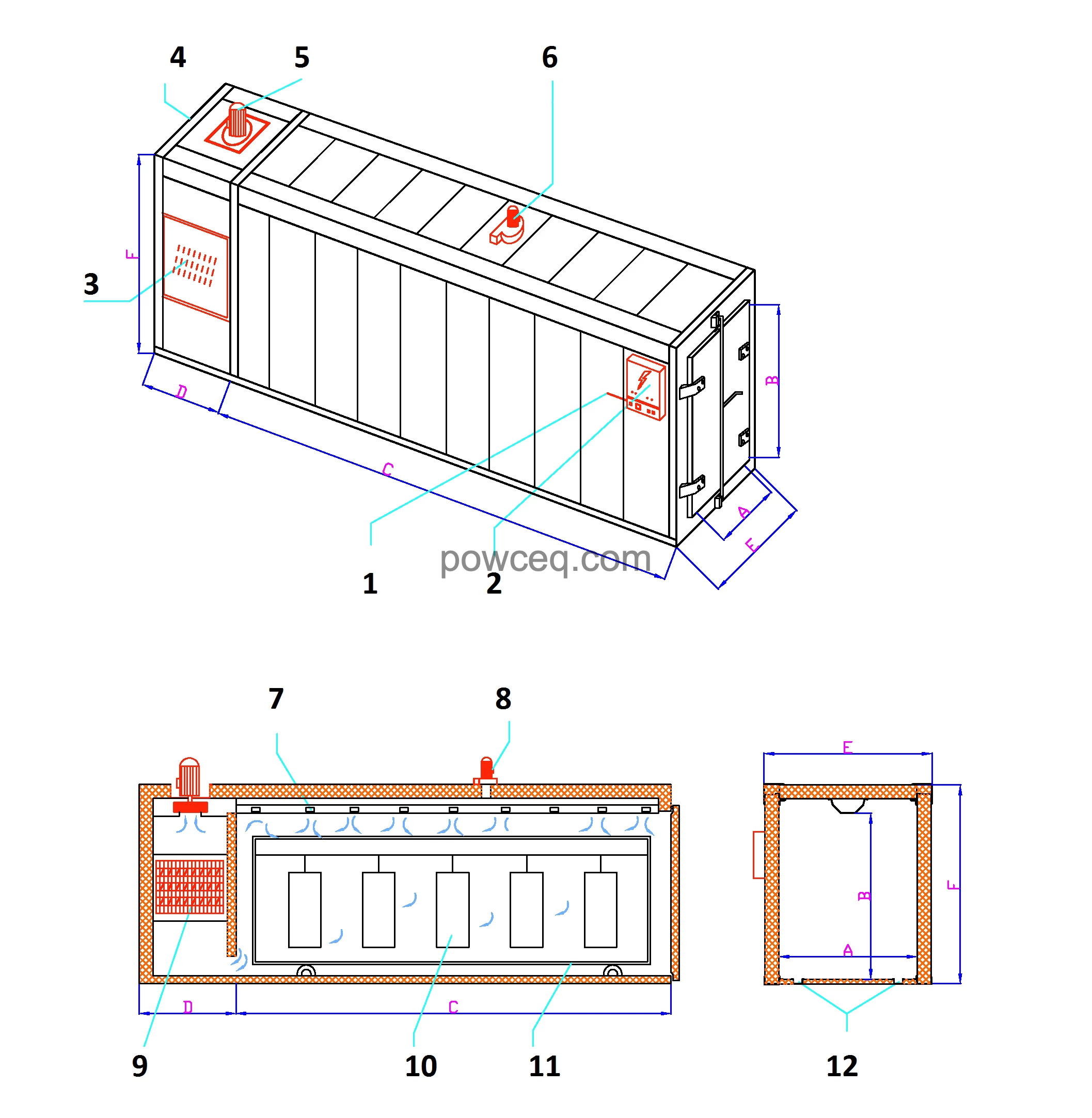

Components curing oven

- Control unit

- Control cabinet

- Heating unit

- Insulating wall

- Circulation fan

- Exhaust fan

- Air canal

- Exhaust fan

- Heating unit

- Workpiece

- Horde trolley

- Rail

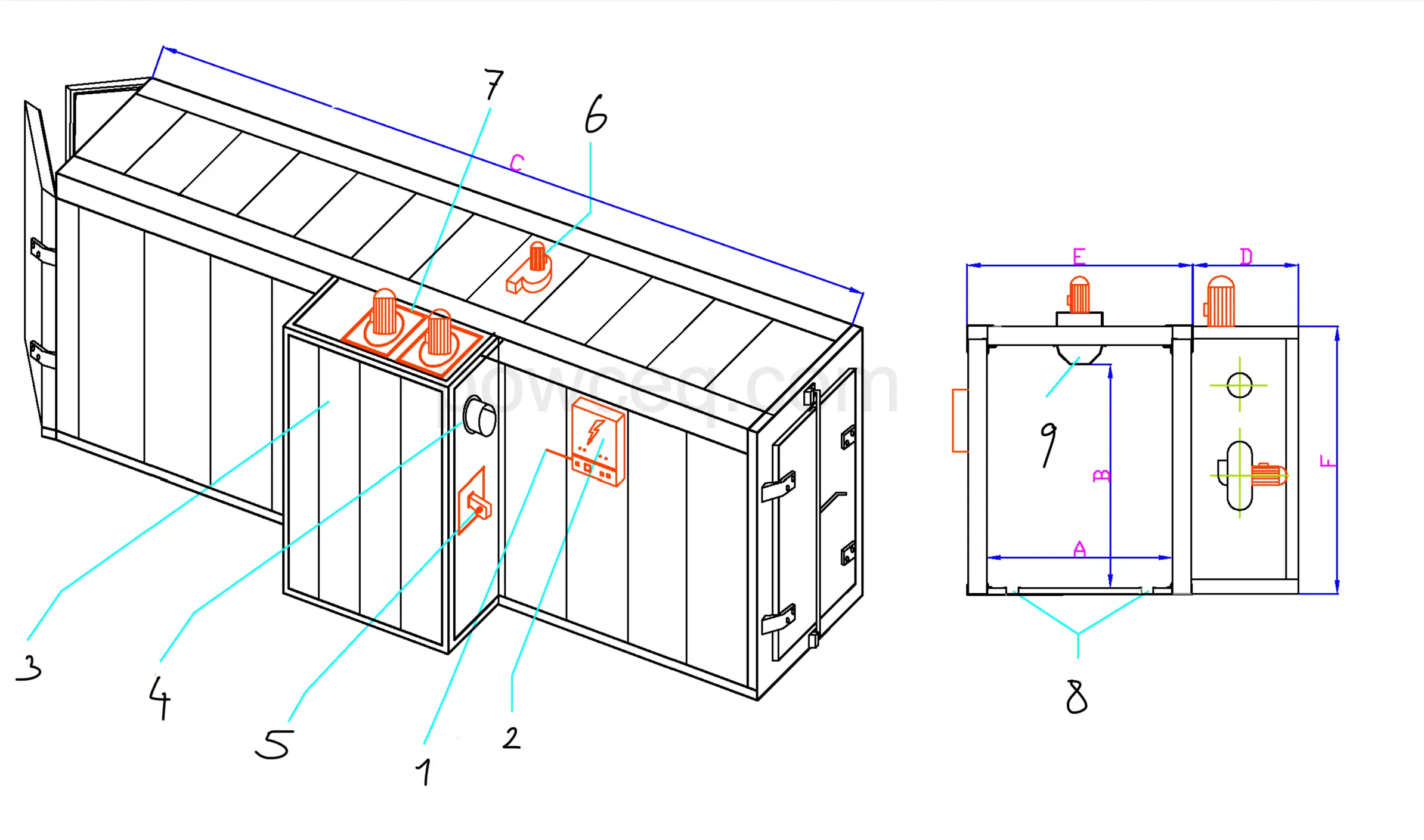

Burner powered heating unit at the side

Doors on both sides, loading over trolley

- Control unit

- Control cabinet

- Heating unit

- Chimney

- Burner, gas or diesel oil

- Exhaust fan

- Circulation fans

- Inner rails for trolley car

- Heating air canal

Gas or diesel oil Burner

Some powder coating ovens use a gas burner as a heat source. These ovens are often more powerful and can reach higher temperatures than their electric counterparts.

Rails and sliding doors

- Control unit

- Control cabinet

- Heating unit

- Insulating wall

- Heating elements

- Exhaust fan

- Overhead rails

- Sliding doors

DIY

Building a DIY powder coating oven sounds to be a cost-effective alternative to purchasing a commercial unit. But in long term cost and security aspect, not recommended.

Safe and Energy-Efficient

Safety and efficiency are our top priorities. Our ovens are designed with safety features to prevent accidents and are energy-efficient, helping you save on operating costs.

Contact Us Today

Ready to take your powder coating process to the next level? Contact us today to learn more about our powder coating ovens and find the perfect one for your needs.

Advanced Temperature Control

With our advanced digital controllers, you can easily set and maintain the desired temperature. This ensures your powder cures properly, resulting in a high-quality finish.

This controller can be an analog device with several probes or a digital PLC.

Importance of Temperature

The temperature in powder coating is crucial as it affects the curing process. Curing is the process where the powder melts and reacts to form a high molecular weight polymer. This polymer provides the coating with its excellent durability and resistance to breakdown.

Optimal Temperature

The optimal temperature for powder coating varies depending on the type of powder used. Epoxy and polyester powders, require a curing temperature of between 320-360°F / 160-180°C and a curing time of 10 to 20 minutes.

However, some powders may require higher temperatures or longer curing times. It is important to follow the manufacturer’s instructions to achieve the best results.

Preheating

Preheating the object to be coated is a vital step in the powder coating process. Preheating helps to improve the powder’s adhesion to the object, ensuring a smooth and even coating. The preheating temperature is usually slightly lower than the curing temperature.

Temperature Uniformity

Uniform temperature is critical in the powder coating oven. Uneven temperatures can lead to an inconsistent finish, with some areas being over-cured and others under-cured. Over-curing can cause discoloration and reduced coating performance, while under-curing can result in poor adhesion and low corrosion resistance.

Temperature Monitoring

Monitoring the temperature within the powder coating oven is crucial to maintain the optimal curing conditions. This is typically done using a digital temperature controller, which allows for precise temperature control.

Impact of Ambient Temperature

The ambient temperature, or the temperature of the surrounding environment, can also impact the powder coating process. In colder environments, it may take longer for the oven to reach the desired temperature, potentially affecting the production speed.

Temperature Recovery

Temperature recovery refers to the oven’s ability to return to the set temperature after the coated object is introduced. A fast temperature recovery ensures that the curing process is not disrupted, leading to a consistent and high-quality finish.

In conclusion

Temperature plays a pivotal role in the powder coating process. It affects the quality of the finish, the adhesion of the powder, and the overall durability of the coating. Therefore, understanding and controlling the temperature is key to achieving a successful powder coating application. Whether you’re a hobbyist or a professional, keeping these temperature considerations in mind will help you get the most out of your powder coating endeavors.

For Sale

Powder coating ovens are available for sale in various sizes and specifications. Some are in stock, others need to be produced which can take several weeks.

Competitive Prices

We believe in providing value for money. Our powder coating ovens are competitively priced without compromising on quality or performance.

Price

The price of a powder coating oven can vary significantly based on its size, features, and the manufacturer. It's important to consider both the initial cost and the ongoing operating costs when evaluating the price.

Indicative offer 6 meter powdercoat oven

Internal dimensions = working area = maximum workpiece size Length x width x depth = 6 x 1.5 x 1.8 m External dimensions approx. (depending on installation) = 7.7 x 1.8 x 2.15 m

approx. 16 m³, calculated heating capacity of the gas burner: 140kW, temp. max. 205°C

Wall channels reinforced and with 150mm 100kg/m³

Rock wool, perfectly insulated

Air output 17,000 m³/h with 2 x 2.2kW motors, 3P 50Hz, 400V

2x hinged doors Rail on the floor for tray trolleys (sliding doors or overhead conveyors also possible) Heat-resistant fans for recirculation and exhaust air Overheating protection

Clear control system, analog is perfectly adequate, as regulation in this temperature range is technically very easy to implement

Digital (Siemens) also possible on request for temperatures up to 450°C

Burner chimney and air ducts are not included in the scope of delivery, as these always have different shapes on site depending on requirements

25+ years of manufacturing experience

Is it worth converting curing ovens?

Frequently asked: Is electric heating cheaper than with a gas burner or oil burner?

As of November 1, 2022, new customer prices HH (commercial or industrial prices in % similar)

One kilowatt hour of electricity costs 48 cents

Gas / oil 21 cents

Assuming the stove requires 100 kW of heating energy with the gas burner.

20.10 € per hour

An electrically heated oven will require 90kW.

43.20 € per hour

A conversion is therefore not worthwhile.

Which manufacturer of powder ovens?

Independent test results from several powder coating manufacturers are available:

Perfect temperature uniformity

Delivery in only approx. 6 weeks

Optimised production line in the factory

Visits possible by appointment

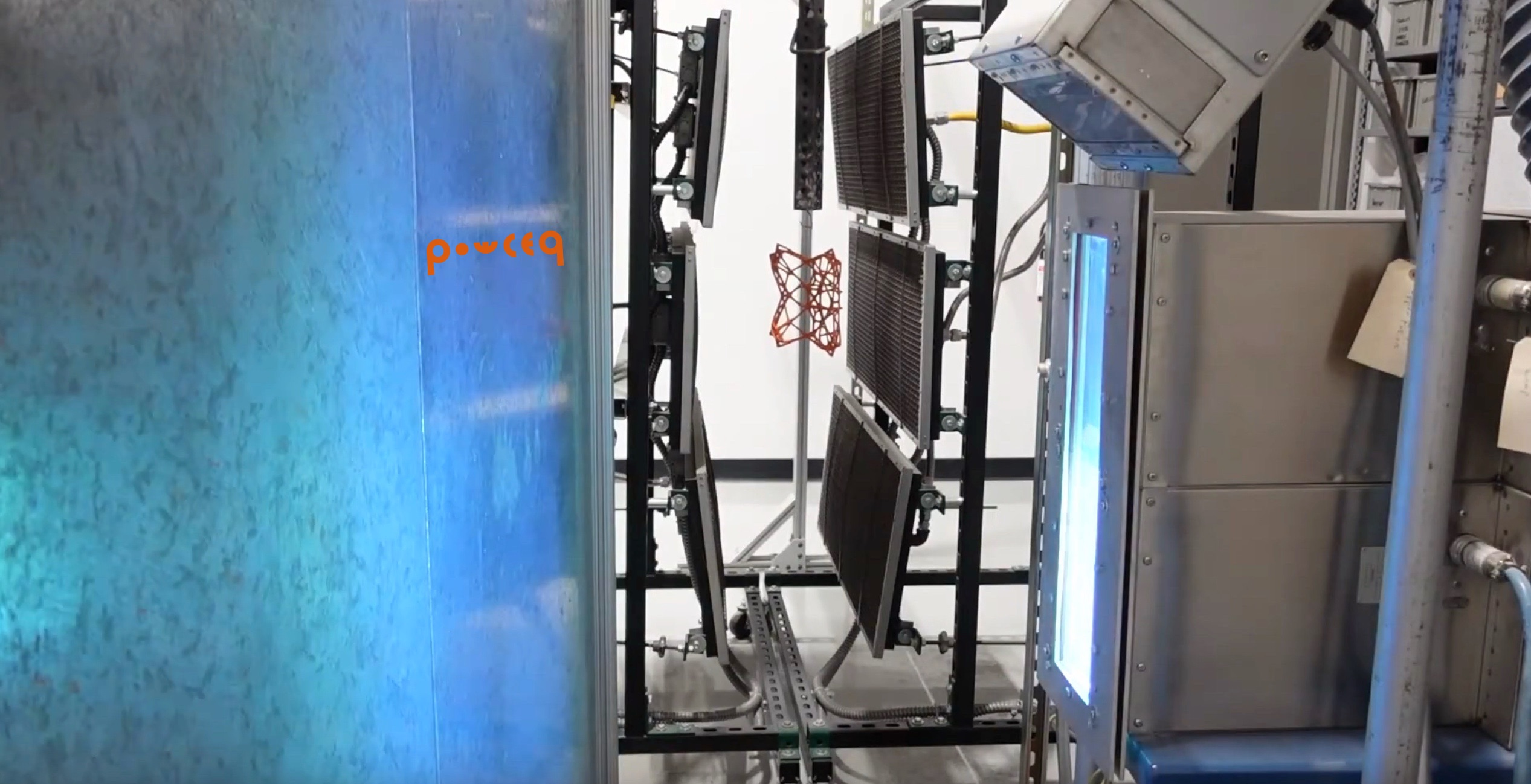

Powder ovens with rail system

5x Rail system with transport trolley

Powder oven control analog

Perfect control of the air flow

Homogeneous air distribution

Precise control up to 200°C

Multiple sensors

Digital powder oven control

PLC digital up to 450°C

PLC = programmable logic controller

Controller

The controller is a key component of a powder coating oven. It regulates the temperature and ensures it remains consistent throughout the curing process.

Energy Saving Heating Types

Convection oven, several fans

- Electric

- Gas / oil burner, indirect

- Gas direct combustion burner

- Hybrid, heats electric or by indirect burner

Infrared oven, no fans

- Electric infrared

- Natural gas catalytic infrared long-wavelength

- Ultraviolet light

Catalytic infrared benefits

Integrating an infrared oven to a automatic powder coating line:

Increases production by 50%& Improves product quality Reduces natural gas consumption by 25% annually Achieves a 3-year simple payback

FAQ - Questions & answers about powder ovens

Powder coating oven for sale

Offer and price

Design and quality

Perfect temperature uniformity

Delivery and start-up

Optimised production line in the factory

Faster delivery

Installation by our technicians

Product Summary

~ We ship anywhere, worldwide

Manual or automatic powder coat spray guns

Powder centers and powder transfer pumps

Powder coating booths, Fast color change booths

Dryer, Oven

Pretreatment lines - automatic washing

Special solutions